Glass

Glass is a non-crystalline, often transparent amorphous solid, that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenching) of the molten form; some glasses such as volcanic glass are naturally occurring. The most familiar, and historically the oldest, types of manufactured glass are "silicate glasses" based on the chemical compound silica (silicon dioxide, or quartz), the primary constituent of sand. Soda-lime glass, containing around 70% silica, accounts for around 90% of manufactured glass. The term glass, in popular usage, is often used to refer only to this type of material, although silica-free glasses often have desirable properties for applications in modern communications technology. Some objects, such as drinking glasses and eyeglasses, are so commonly made of silicate-based glass that they are simply called by the name of the material.

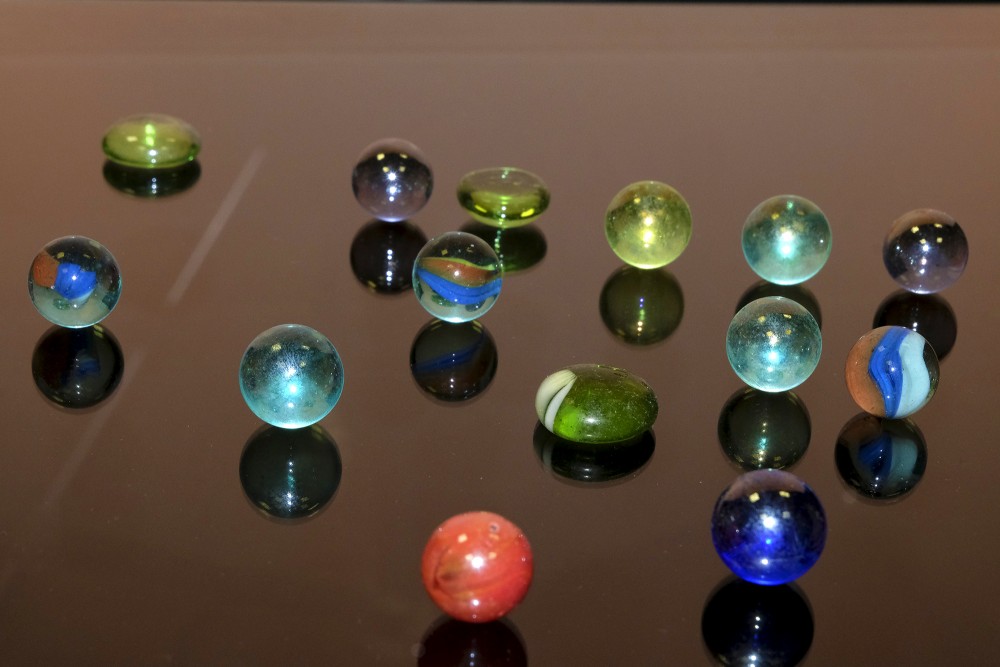

Although brittle, silicate glass is extremely durable and many examples of glass fragments exist from early glass-making cultures. Archaeological evidence suggests glass-making dates back to at least 3,600 BC in Mesopotamia, Egypt, or Syria. The earliest known glass objects were beads, perhaps created accidentally during metalworking or the production of faience. Due to its ease of formability into any shape, glass has been traditionally used for vessels, such as bowls, vases, bottles, jars and drinking glasses. In its most solid forms, it has also been used for paperweights and marbles. Glass can be coloured by adding metal salts or painted and printed with vitreous enamels, leading to its use in stained glass windows and other glass art objects.

The refractive, reflective and transmission properties of glass make glass suitable for manufacturing optical lenses, prisms, and optoelectronics materials. Extruded glass fibres have application as optical fibres in communications networks, thermal insulating material when matted as glass wool so as to trap air, or in glass-fibre reinforced plastic (fibreglass).

Occurrence in nature

Glass can form naturally from volcanic magma. Obsidian is a common volcanic glass with high silica (SiO2) content formed when felsic lava extruded from a volcano cools rapidly. Impactite is a form of glass formed by the impact of a meteorite, where Moldavite (found in central and eastern Europe), and Libyan desert glass (found in areas in the eastern Sahara, the deserts of eastern Libya and western Egypt) are notable examples. Vitrification of quartz can also occur when lightning strikes sand, forming hollow, branching rootlike structures called fulgurites. Trinitite is a glassy residue formed from the desert floor sand at the Trinity nuclear bomb test site. Edeowie glass, found in South Australia, is proposed to originate from Pleistocene grassland fires, lightning strikes, or hypervelocity impact by one or several asteroids or comets.

History

Naturally occurring obsidian glass was used by Stone Age societies as it fractures along very sharp edges, making it ideal for cutting tools and weapons. Glassmaking dates back to at least 6000 years, long before humans had discovered how to smelt iron. Archaeological evidence suggests that the first true synthetic glass was made in Lebanon and the coastal north Syria, Mesopotamia or ancient Egypt. The earliest known glass objects, of the mid-third millennium BC, were beads, perhaps initially created as accidental by-products of metalworking (slags) or during the production of faience, a pre-glass vitreous material made by a process similar to glazing. Early glass was rarely transparent and often contained impurities and imperfections, and is technically faience rather than true glass, which did not appear until the 15th century BC. However, red-orange glass beads excavated from the Indus Valley Civilization dated before 1700 BC (possibly as early as 1900 BC) predate sustained glass production, which appeared around 1600 in Mesopotamia and 1500 in Egypt. During the Late Bronze Age there was a rapid growth in glassmaking technology in Egypt and Western Asia. Archaeological finds from this period include coloured glass ingots, vessels, and beads. Much early glass production relied on grinding techniques borrowed from stoneworking, such as grinding and carving glass in a cold state.

The term glass developed in the late Roman Empire. It was in the Roman glassmaking centre at Trier (located in current-day Germany), that the late-Latin term glesum originated, probably from a Germanic word for a transparent, lustrous substance.Glass objects have been recovered across the Roman Empirein domestic, funerary, and industrial contexts.Examples of Roman glass have been found outside of the former Roman Empire in China,the Baltics, the Middle East, and India.The Romans perfected cameo glass, produced by etching and carving through fused layers of different colours to produce a design in relief on the glass object.

In post-classical West Africa, Benin was a manufacturer of glass and glass beads.Glass was used extensively in Europe during the Middle Ages. Anglo-Saxon glass has been found across England during archaeological excavations of both settlement and cemetery sites.From the 10th-century onwards, glass was employed in stained glass windows of churches and cathedrals, with famous examples at Chartres Cathedral and the Basilica of Saint Denis. By the 14th-century, architects were designing buildings with walls of stained glass such as Sainte-Chapelle, Paris, (1203–1248) and the East end of Gloucester Cathedral. With the change in architectural style during the Renaissance period in Europe, the use of large stained glass windows became much less prevalent,although stained glass had a major revival with Gothic Revival architecture in the 19th century.

During the 13th century, the island of Murano, Venice, became a centre for glass making, building on medieval techniques to produce colourful ornamental pieces in large quantities. Murano glass makers developed the exceptionally clear colourless glass cristallo, so called for its resemblance to natural crystal, and extensively used for windows, mirrors, ships' lanterns, and lenses.In the 13th, 14th, and 15th centuries, enamelling and gilding on glass vessels was perfected in Egypt and Syria.Towards the end of the 17th century, Bohemia became an important region for glass production, remaining so until the start of the 20th century. By the 17th century, glass was also being produced in England in the Venetian tradition. In around 1675, George Ravenscroft invented lead crystal glass, with cut glass becoming fashionable in the 18th century.Ornamental glass objects became an important art medium during the Art Nouveau period in the late 19th century.

Throughout the 20th century, new mass production techniques led to the widespread availability and utility for bulk glass and its increased use as a building material and new applications of glass.In the 1920s a mould-etch process was developed, in which art was etched directly into the mould, so that each cast piece emerged from the mould with the image already on the surface of the glass. This reduced manufacturing costs and, combined with a wider use of coloured glass, led to cheap glassware in the 1930s, which later became known as Depression glass. In the 1950s, Pilkington Bros., England, developed the float glass process, producing high-quality distortion free flat sheets of glass by floating on molten tin.Modern multi-story buildings are frequently constructed with curtain walls made almost entirely of glass.Similarly, laminated glass has been widely applied to vehicles for windscreens.Optical glass for spectacles has been used since the Middle Ages.The production of lenses has become increasingly proficient, aiding astronomers as well as having other application in medicine and science.Glass is also employed as the aperture cover in many solar energy collectors.

In the 21st century, glass manufacturers have developed different brands of chemically strengthened glass for widespread application in touchscreens for smartphones, tablet computers, and many other types of information appliances. These include Gorilla glass, developed and manufactured by Corning, AGC Inc.'s Dragontrail and Schott AG's Xensation.

Physical properties

Optical

Glass is in widespread use in optical systems due to its ability to refract, reflect, and transmit light following geometrical optics. The most common and oldest applications of glass in optics are as lenses, windows, mirrors, and prisms. The key optical properties refractive index, dispersion, and transmission, of glass are strongly dependent on chemical composition and, to a lesser degree, its thermal history. Optical glass typically has a refractive index of 1.4 to 2.4 and Abbe number, which characterises dispersion, of 15 to 100. Refractive index may be modified by high-density (refractive index increases) or low-density (refractive index decreases) additives.

Glass transparency results from the absence of grain boundaries which diffusely scatter light in polycrystalline materials. Semi-opacity due to crystallization may be induced in many glasses by maintaining them for a long period at a temperature just insufficient to cause fusion. In this way, the crystalline, devitrified material, known as Réaumur's glass porcelain is produced. Although generally transparent to visible light, glasses may be opaque to other wavelengths of light. While silicate glasses are generally opaque to infrared wavelengths with a transmission cut-off at 4 μm, heavy-metal fluoride and chalcogenide glasses are transparent to infrared wavelengths of 7 to 18 μm, respectively.The addition of metallic oxides results in different coloured glasses as the metallic ions will absorb wavelengths of light corresponding to specific colours.

Other

In the manufacturing process, glasses can be poured, formed, extruded and moulded into forms ranging from flat sheets to highly intricate shapes. The finished product is brittle and will fracture, unless laminated or tempered to enhance durability. Glass is typically inert, resistant to chemical attack, and can mostly withstand the action of water, making it an ideal material for the manufacture of containers for foodstuffs and most chemicals. Nevertheless, although usually highly resistant to chemical attack, glass will corrode or dissolve under some conditions. The materials that make up a particular glass composition have an effect on how quickly the glass corrodes. Glasses containing a high proportion of alkali or alkaline earth elements are more susceptible to corrosion than other glass compositions.

The density of glass varies with chemical composition with values ranging from 2.2 grams per cubic centimetre (2,200 kg/m3) for fused silica to 7.2 grams per cubic centimetre (7,200 kg/m3) for dense flint glass.Glass is stronger than most metals, with a theoretical tensile strength estimated at 14 gigapascals (2,000,000 psi) to 35 gigapascals (5,100,000 psi) due to its ability to undergo reversible compression without fracture. However, the presence of scratches, bubbles, and other microscopic flaws lead to a typical range of 14 megapascals (2,000 psi) to 175 megapascals (25,400 psi) in most commercial glasses.Several processes such as toughening can increase the strength of glass.Carefully drawn flawless glass fibres can be produced with strength of up to 11.5 gigapascals (1,670,000 psi).

Reputed flow

The observation that old windows are sometimes found to be thicker at the bottom than at the top is often offered as supporting evidence for the view that glass flows over a timescale of centuries, the assumption being that the glass has exhibited the liquid property of flowing from one shape to another.This assumption is incorrect, as once solidified, glass stops flowing. Instead, glass manufacturing processes in the past produced sheets of non-uniform thickness leading to observed sagging and ripples in old windows.

Colour

Colour in glass may be obtained by addition of homogenously distributed electrically charged ions (or colour centres). While ordinary soda-lime glass appears colourless in thin section, iron(II) oxide (FeO) impurities produce a green tint in thick sections. Manganese dioxide (MnO2), which gives glass a purple colour, may be added to remove the green tint given by FeO. FeO and chromium(III) oxide (Cr2O3) additives are used in the production of green bottles. Iron (III) oxide, on the other-hand, produces yellow or yellow-brown glass.Low concentrations (0.025 to 0.1%) of cobalt oxide (CoO) produces rich, deep blue cobalt glass. Chromium is a very powerful colourising agent, yielding dark green. Sulphur combined with carbon and iron salts produces amber glass ranging from yellowish to almost black.A glass melt can also acquire an amber colour from a reducing combustion atmosphere. Cadmium sulfide produces imperial red, and combined with selenium can produce shades of yellow, orange, and red.The additive Copper(II) oxide (CuO) produces a turquoise colour in glass, in contrast to Copper(I) oxide (Cu2O) which gives a dull brown-red colour.

en.wikipedia.org

https://en.wikipedia.org/wiki/Glass

Continue reading